Commercial kitchens never slow down. With constant turnover, seasonal hiring surges, and shifting roles, there is always someone new who needs to get trained—fast. Training typically falls on store managers and experienced line staff. They show new hires the ropes, walk them through procedures, and make sure operations run smoothly. But building a reliable operation on word-of-mouth training and hoping the right person is working that shift is not a sustainable strategy. When training breaks down, the impact is immediate. Food quality becomes inconsistent. Equipment gets misused. Service slows down. Safety risks increase.

The solution does not require more staff. It requires smarter equipment data—and that is where Open Kitchen makes a difference.

The Core Challenge: Equipment Inconsistency

Most multi-unit restaurant brands want the same procedures at every location. Reality looks different:

Some locations have newer equipment. Others are running older units. Settings drift over time. Maintenance schedules vary based on staffing and workload. New employees learn from whoever is available—not necessarily the person who knows the correct procedures.

This is not about motivation. It is about trying to teach consistency when the equipment itself is not consistent.

How Open Kitchen Transforms the Training Process

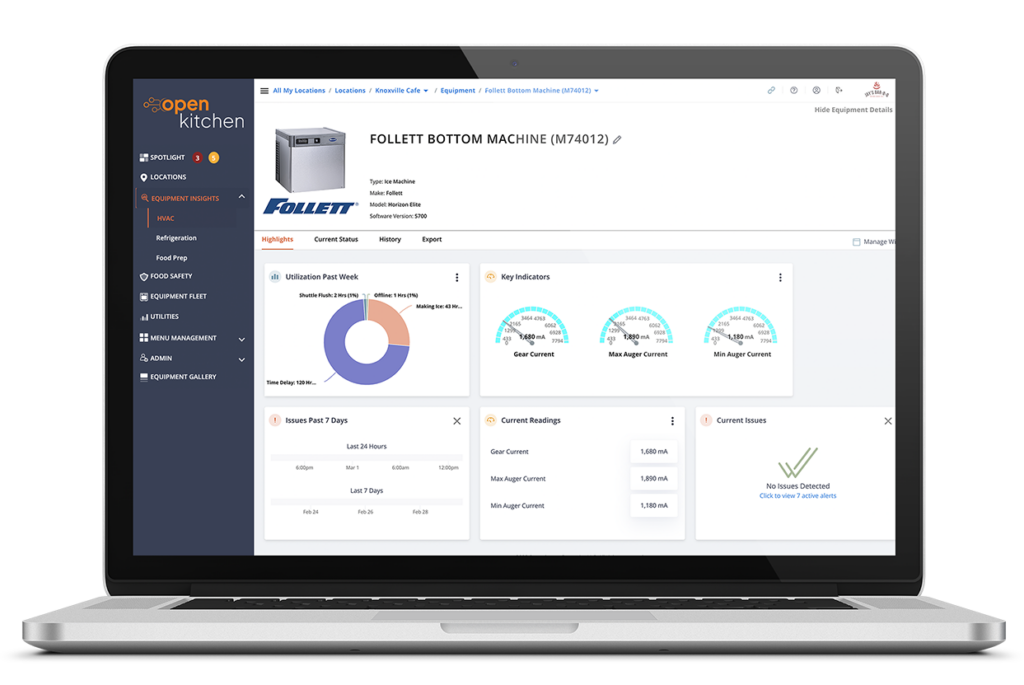

The Open Kitchen platform connects equipment across all locations, creating a foundation for faster, more reliable training. When equipment is connected and feeding real insights through an IoT platform, training becomes more efficient.

Standardized settings deployed automatically. With Open Kitchen, operators can push standardized cooking and holding settings to all connected equipment remotely. When cook temperatures, times, and modes are configured correctly by default across ovens, fryers, and holding equipment, there is less for new hires to memorize and fewer opportunities for error.

Real-time equipment guidance. Instead of relying on laminated instruction sheets, connected equipment provides in-the-moment alerts based on actual performance data:

- Excessive idle time detected—equipment running unnecessarily

- Ignition fault identified—service may be required

- Unusual door open frequency—impacting temperature recovery

- Oil usage exceeding normal levels—check for leaks or operational issues

The equipment becomes part of the training process.

Visibility into training effectiveness. Open Kitchen monitors proper equipment usage during service, revealing where training gaps exist. Performance data identifies human patterns as clearly as technical issues:

- Are burn rates higher on certain shifts?

- Are cleaning cycles repeatedly skipped at specific stores?

- Does food quality decline when turnover spikes?

Automated reminders tied to actual equipment conditions—not static schedules—help ensure best practices are followed consistently.

Location-level insights for targeted support. The platform identifies which locations need additional training or support before small issues become larger problems. This allows operators to be proactive instead of reactive.

What This Means for Multi-Unit Operators

When operations are not dependent on institutional knowledge or who happens to be working a shift, performance becomes more stable and predictable. New employees get up to speed faster because they are supported by consistent equipment behavior, not informal workarounds or verbal instructions that vary by location.

Equipment is used correctly more often, which reduces unnecessary wear, lowers repair costs, and prevents avoidable failures. Food quality improves when cooking and holding temperatures remain consistent across locations, leading to a more reliable guest experience and stronger brand trust.

Most importantly, managers and experienced staff spend less time correcting mistakes or retraining the same processes. With fewer disruptions and less hands-on oversight required, teams can focus on running the business instead of constantly compensating for gaps in training.

Improving labor outcomes is not about adding more training materials or longer onboarding sessions. It is about making training easier to execute successfully—and consistency makes that possible.

The Open Kitchen Advantage

Many restaurant brands use Open Kitchen to reduce onboarding time and maintain consistent food quality across every location. The cloud-based platform brings equipment performance, training support, and operational visibility together in one solution.

Learn more about how we support restaurant operators, or explore the full capabilities of the Open Kitchen foodservice platform.

Employees should not have to memorize how every piece of equipment behaves. The equipment should enable good habits—not depend on them.

Final Thought

The guest experience does not start when food reaches the customer. It starts when a new employee clocks in for the first time. When equipment supports the training process with consistency, real-time guidance, and transparency across all locations, operators build stronger teams, reduce failures, and improve the bottom line.

Ready to improve training consistency across your locations? Request a demo and talk to our team.