Thought Leadership

How to Prevent Refrigeration Breakdowns in Summer’s Peak Season

Prevent costly downtime this summer—learn how high heat and holiday surges strain commercial kitchen refrigeration equipment in July.

Prevent costly downtime this summer—learn how high heat and holiday surges strain commercial kitchen refrigeration equipment in July.

Thought Leadership

Prevent costly downtime this summer—learn how high heat and holiday surges strain commercial kitchen refrigeration equipment in July.

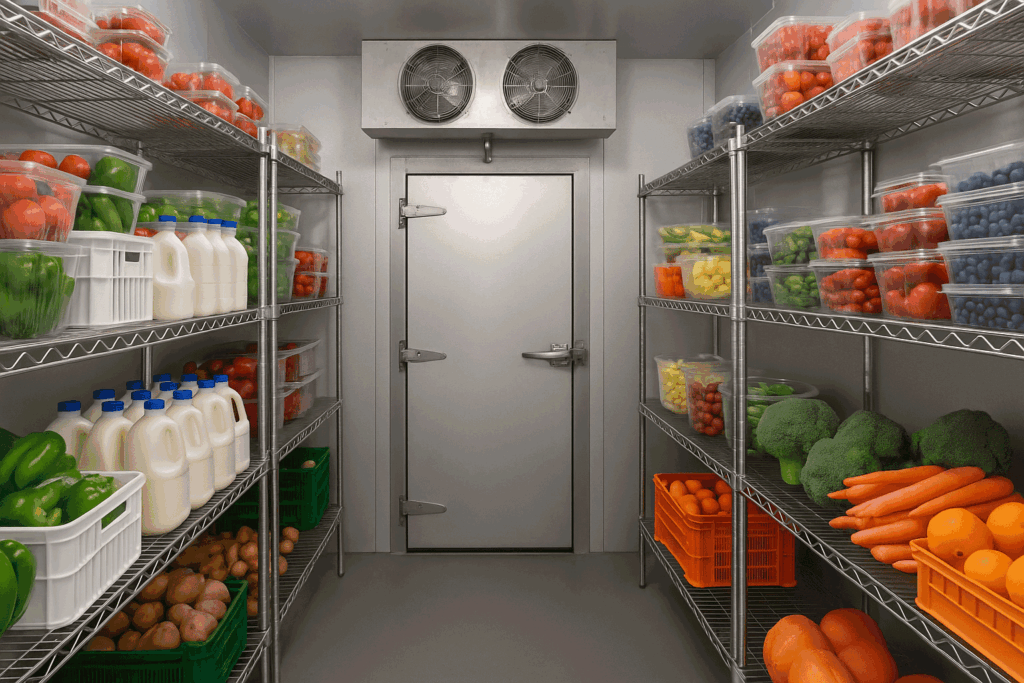

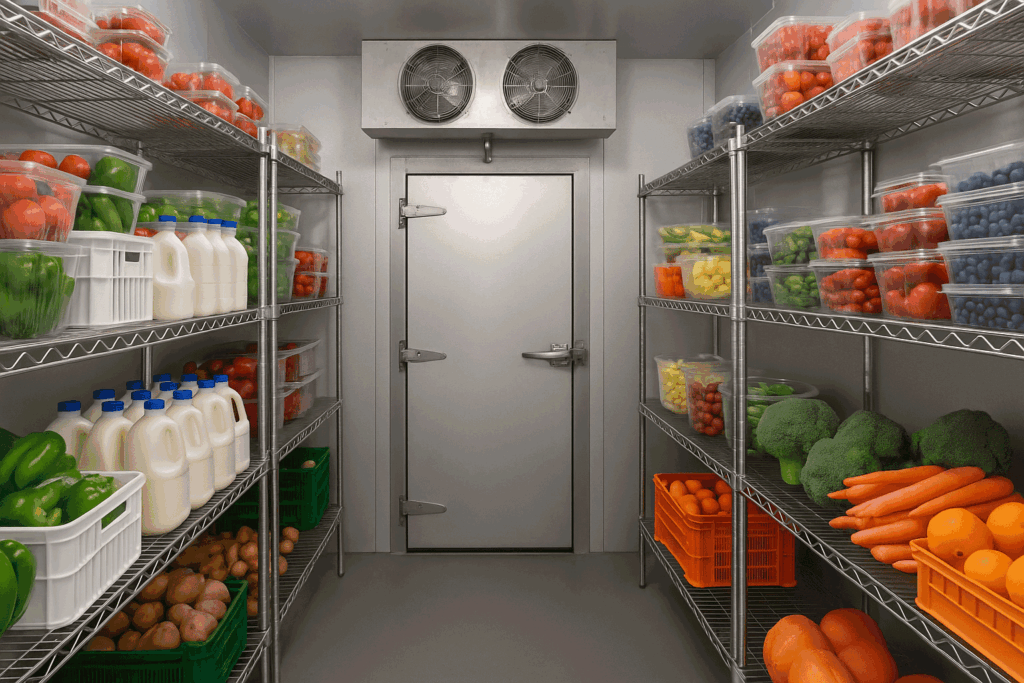

As temperatures soar in July, commercial kitchens face more than just rising utility bills—they face real strain on their refrigeration equipment. From walk-in coolers to undercounter units and ice machines, high ambient temperatures can push cooling systems to the brink. Add in holiday surges like July 4th and peak summer dining traffic, and it’s easy to see why refrigeration issues are one of the top causes of costly downtime this time of year.

But with the right tools and a proactive approach, restaurant operators can keep their kitchens cool—and their business running smoothly.

When a refrigeration unit fails during peak hours, the impact is immediate and expensive. Spoiled inventory, health code violations, unhappy customers, and service disruptions can all follow. Even brief temperature fluctuations can compromise food safety and require product disposal to remain compliant with HACCP standards.

Higher ambient temperatures force refrigeration systems to work harder, increasing energy consumption and the likelihood of overheating.

Hot air intrusion from worn gaskets or frequent door openings makes it harder for units to maintain safe internal temperatures.

Summer beverage demand pushes ice machines to their limits, often leading to clogged filters, scale buildup, or sensor malfunctions.

Here are actionable steps operators can take to reduce refrigeration risk this July:

Traditional maintenance schedules can’t always keep up with summer stress. The Open Kitchen® platform uses IoT-powered monitoring to deliver real-time insight and early warning for refrigeration issues. Operators gain:

With Open Kitchen®, operators can create custom alert thresholds, track system behavior over time, and schedule service only when the data indicates it’s needed—saving time, money, and inventory.

If your kitchen is operating near the edge in July, you’re not alone. But you don’t have to accept equipment failure as part of peak season. A data-driven approach to refrigeration monitoring and preventive maintenance can keep your cold storage consistent, your product safe, and your guests happy.

Ready to cool down the chaos? Talk to our team or Email us to learn how Open Kitchen® can help your refrigeration systems perform—no matter how hot it gets outside.